ZHEJIANG HANJIA TECHNOLOGY CO., LTD.

XINCHANG BROTHER TOOLS CO., LTD.

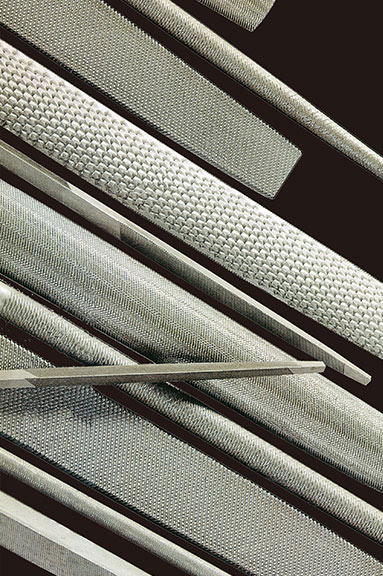

Although the shapes of Rasp Plane structural analysis files are square, triangular and cylindrical, their main processing surface shapes are the same. In the length direction, all kinds of files have a certain arc and taper. Most people often ignore this point. They think that as long as the end of the file is flat and the hand moves horizontally, the required workpiece can be filed. In fact, this is a misunderstanding.

From the shape of the file, we can see that on the entire processing surface, the file has a horizontal plane at the shank, and there is an obvious curved arc at two-thirds of the way. Observe the working surface of the file perpendicular to the horizontal plane. , you will find that the file surface is not straight. Theoretically, even if your hands move horizontally, the movement of the blade surface of the file is not straight, and its movement trajectory changes.

We know that the machining allowance of filing is generally not large. Manual filing mainly relies on physical strength as the driving force, and this driving force is not constant, but changes with time and the decline of human physical strength, which is not good for filing work. .

2. The correct method of filing is to keep the horizontal motion state as far as possible during filing. When the rake face of the file is pushed forward on the workpiece, use a little force with your left hand and keep your right hand balanced; in the rear section, use your right hand with force while keeping your left hand balanced. Then, the effect of filing is judged by observing the filing pattern. For example, if cross filing is used, the processing condition of the filing plane can be clearly known from the mutual combination of the textures, which is convenient for adjusting the force direction of the filing and maintaining the smoothness of the machining plane at any time. Consistency; make measurements at the same time, and make records after each measurement, so as to refer to the control and guide the processing.

If it is found that the texture processing of the filing is uneven, or there is an error in the size and shape of the measurement, this phenomenon is mostly caused by the convex and slump angle in the processing surface, and the commonly known "loach back" appears on the entire processing surface. This is due to the incorrect technique. Unsteady force and filing, or simply not understanding the shape and performance of the file. At this time, in order to eliminate the convex phenomenon and avoid the convex phenomenon of filing, the arc surface of the file mentioned earlier should be used.

Use the circular arc on the file to process the plane. It is necessary to consciously and purposely remove the convex surface of the machined part. At the same time, measure it several times and compare it with the angle ruler and feeler gauge until the qualified product is filed. Be careful not to machine the workpiece into a concave shape using the arc surface. At the same time, this method can be extended to the processing of round holes, square holes and keyways.

3. The selection of the thickness of the file and the reserved machining amount The selection of the file is also a more delicate issue, which is mainly determined according to the requirements of the workpiece on the surface roughness and accuracy. The general principle is: coarse grain for roughing, medium and fine grain for semi-finishing, and fine grain and glossy file for finishing.

After the file is selected, it is also important to reserve the machining allowance. Since the workpieces to be filed are generally not large, in theory, the filing allowance should not exceed 0.5 mm; if the workpiece is large and the allowance is large, it is obviously time-consuming, labor-intensive and uneconomical to file. Machining should be considered. In addition, the following issues should be paid attention to when filing.

(1) Don't use too much force when rasp, don't think that rasp can remove the most margin in the shortest time. The rasp should be especially careful, because the rasp is relatively less sharp, and if you are not careful, it is easy to gnaw the machined surface, resulting in deep machining marks, and it is not easy to remove the rough machining in semi-finishing and finishing. Knife marks. At the same time, due to the relatively few blades of the coarse-toothed file, too much force will easily make it blunt and wear out quickly, and the chips will be too large and hidden in the blade, which will affect the filing efficiency of the file and reduce the service life of the file. . In the filing operation, push forward with force, and gently lift and pull back when backward, so as to avoid the wear of the back corner of the file blade and scratch the machined surface, and improve the life of the file.

(2) When semi-finishing, apply chalk ash on the fine file to reduce the chip space, so that the file can be kept sharp, and the surface of the workpiece can be prevented from being scratched by too much chips in the chip groove.

(3) When finishing, the use of a file is more particular, and it is required to choose a fine file and a glossy file. When using the knife, use the knife according to the feel of the knife, and apply force according to the machining allowance. As long as the correct operation method is strictly followed, the workpiece that meets the surface roughness and precision requirements can be machined.

(4) Do not use whetstone and emery cloth when filing. As long as you master the correct filing skills, the processed workpiece will definitely meet the requirements of the drawing. If whetstone and emery cloth are used, the processing texture will be damaged, and if the operation is improper, the edges and corners of the workpiece will be deformed, making the workpiece look lacking in beauty and texture.

NO: BR20007

NO: BR24011

NO: BR25171